Electropolish

Electropolishing of stainless steel is the most common use of the process. Although nearly any metal will work, the most commonly electropolished metals are 300- and 400-series stainless steel. Parts made from 400-series stainless steel have the advantage of increased hardness and strength but the trade-off is increased susceptibility to corrosion. By electropolishing stainless steel, engineers can use 400-series SS and still provide protection from corrosion.

Electropolishing is an electrochemical finishing process that removes a thin layer of material from a metal part, typically stainless steel or similar alloys. The process

A Shiny Finish

Electropolishing, also known as electrochemical polishing, anodic polishing, or electrolytic polishing, is an electrochemical process that removes material from a metallic workpiece, reducing the surface roughness by levelling micro-peaks and valleys, improving the surface finish.

Used In Many Industries

Due to its ease of operation and its usefulness in polishing irregularly-shaped objects, electropolishing has become a common process in the production of semiconductors.

As electropolishing can also be used to sterilize workpieces, the process plays an essential role in the food, medical, and pharmaceutical industries

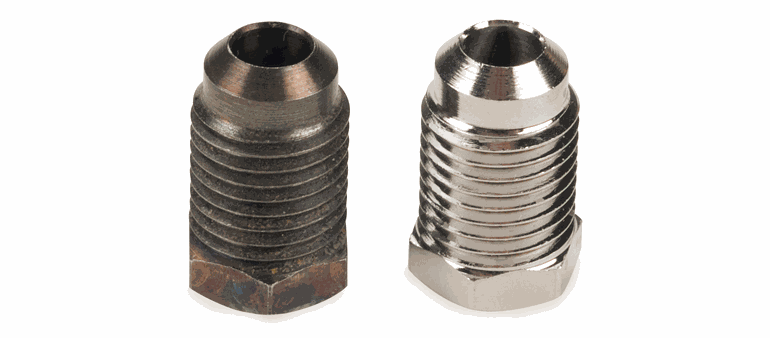

Before and After

Creates a clean, smooth surface that is easier to sterilise.

Can polish areas that are inaccessible by other polishing methods.